The $2,100/Hour Downtime Problem

For rental companies, aerial platform downtime costs $1,400–$2,100 daily (Herc Rentals data). Slewing drives account for 23% of mechanical failures – but strategic management cuts these incidents by 60%.

3 Rental-Specific Optimization Strategies

-

Fleet Standardization

-

Use uniform slewing drives across brands (e.g., JLG/Snorkel compatible units)

-

Result: 70% fewer spare parts + 40% faster repairs

-

-

Damage Prevention Tactics

Failure Cause Prevention Solution Operator overloading IoT torque sensors + auto-shutdown at 105% load Debris ingress Magnetic drain plugs + 3-stage filter housings Improper transport Locking pins with RFID usage tracking -

Lease-Friendly Upgrades

-

Quick-swap modular drives: Replace in 45 minutes vs. 4 hours

-

Telematics-ready: Monitor backlash/temperature via LoRaWAN

-

Case Study: United Rentals’ Western Division

-

Implemented standardized Rotork TDRV-32 drives across 380 boom lifts

-

Results:

✓ 28% reduction in drive-related downtime

✓ $217,000 annual parts savings

✓ 95% lease renewal rate (vs. 78% industry avg)

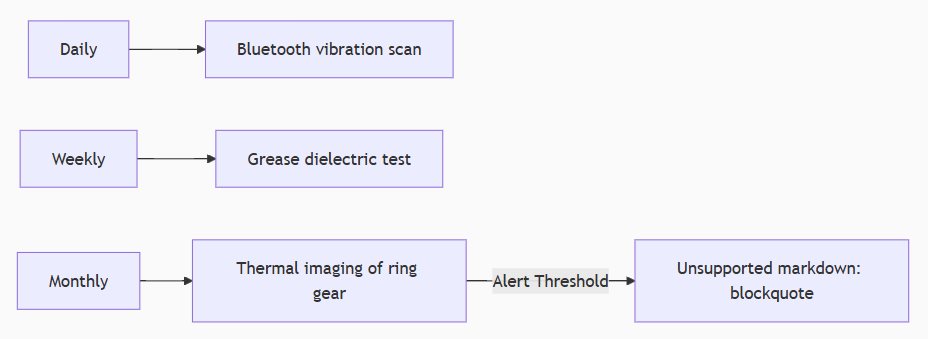

Predictive Maintenance Protocol

Financial Impact

Proactive maintenance cost: $1,250/drive/year

Reactive failure cost: $6,800+/incident

ROI: 82% in first year (ARA benchmark)