The company constantly increase the production capacity of hydraulic central rotary joints and crawler tensioning devices for construction machinery to meet costumers’ demands for large-scale delivery.

There is good working atmosphere, individual respects and cooperates with each other. Implement the Six sigma tools, 15 guiding principles and continuous improvement. Improve the production efficiency with production workers who have working passions. Improve the customer satisfaction and solidate competitive advantages.

With continuous accumulation, Changling Hydraulics has been worked on lean production model, implemented the reform of digital workshops as well as successfully built supply chain management which starts from order demand to making planning, then manufacturing products and delivery. This can meet customers' demands featured by multi-variety, small-batch and delivery on time.

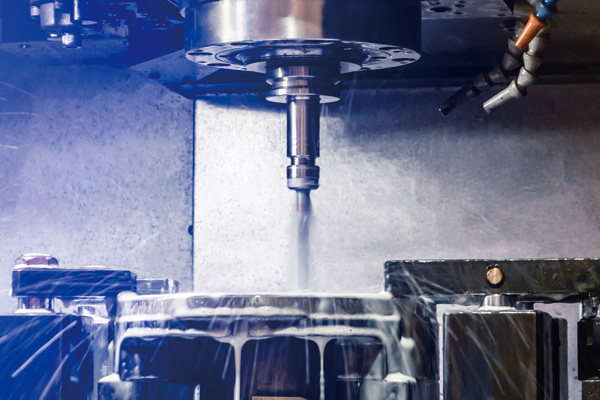

With years of research and development on hydraulic key components in the field of construction machinery, Changling Hydraulics has had intelligent production lines from precision machining process to final assembly process. Changling Hydraulics also has complete sets of testing equipment, including air leakage testing equipment, durability testing equipment, type testing equipment, etc.

With independent research and innovation abilities, Changling Hydraulics has solved the manufacturing process of ultra-multi-channel hydraulic slewing devices and has terminated the long-term monopoly of foreign technology. Our products are widely used in shield tunnel machines, offshore operation platforms, port operation vehicles, aerial work platforms, and large-tonnage crawler cranes, etc.